March 19, 2025

Maintaining OSHA Compliance and Employee Safety in Radiology

- by Shanon Moore, Director, OSHA/HIPAA Compliance

Radiology departments play a critical role in patient care but also present unique workplace hazards requiring special attention. From radiation exposure to ergonomic risks and chemical handling, radiology professionals face multiple safety challenges every day. That’s why OSHA compliance and proactive safety measures are essential – not only to meet regulatory requirements but to foster a culture of safety that protects employees.

The Occupational Safety and Health Administration (OSHA) requires employers to protect workers from exposure to ionizing radiation sources that are not regulated by the Nuclear Regulatory Commission (NRC) or other federal agencies. States also regulate occupational exposure to ionizing radiation, and State Plans may have more stringent requirements when compared to federal requirements.

Ionizing Versus Non-Ionizing Radiation

Radiation exists all around us, from both natural and manmade sources, and is in two forms: ionizing and non-ionizing radiation.

- Ionizing radiation is a form of energy that acts by removing electrons from atoms and molecules of materials. Ionizing radiation can travel unseen and pass through materials such as air, water, and living tissue.

- Non-ionizing radiation differs from ionizing radiation in the way it acts on these materials. Unlike x-rays and other forms of ionizing radiation, non-ionizing radiation does not have enough energy to remove electrons.

Medical diagnostic exams are the primary manmade source of ionizing radiation exposure in the United States. At high enough doses, ionizing radiation can alter the body’s cells and DNA and cause serious harm or cancer with enough exposure.

Under OSHA’s Ionizing Radiation standard (29 CFR 1910.1096), employers must:

- Monitor occupational exposure and dose limits

- Survey radiation hazards in order to comply with the standard

- Supply appropriate personal protective equipment

- Post caution signs, labels, and signals

- Provide instruction and training to personnel and post-operating procedures

Exposure Monitoring

Employers are required to supply appropriate personal monitoring equipment, such as film badges, pocket chambers, pocket dosimeters, or film rings. Any employee entering a restricted area that is likely to receive a dose in any calendar quarter in excess of 25% of the applicable occupational limit is required to use monitoring equipment. Employees under 18 years of age are not permitted to receive a dose in any period of one calendar quarter that exceeds 10% of the limit noted in the first bullet below.

Quarterly Limits:

- Whole body: head and trunk; active blood-forming organs; lens of eyes; or gonads: 1.25 rem

- Hands and forearms; feet and ankles: 18.75 rem

- Skin of whole body: 7.5 rem

Hazard Assessments

Compliance includes surveying radiation hazards in order to comply with the standard. Employers should conduct hazard assessments to determine what safety and health hazards workers may encounter and identify engineering controls and administrative controls that should be followed to protect workers. Key components of surveying these hazards include:

- Conduct an initial inspection of all work areas with radiation exposure

- Create checklists and a schedule for regular inspections

- Follow up to correct recognized hazards or hazardous situations

Personal Protective Equipment

Personal protective equipment (PPE) is used to prevent workers from becoming contaminated with radioactive material. Commonly used PPE for radiation protection from X-rays include:

- Lead aprons or vests are worn to reduce a worker’s radiation dose.

- Thyroid collars offer additional protection for the thyroid gland, which is particularly sensitive to radiation.

- Lead-lined gloves offer protection for workers from radiation exposure to the hands and should be used for some X-ray equipment if hands must be placed in the direct X-ray field.

- Safety goggles such as leaded eyewear or opaque safety goggles can protect a worker’s eyes from radiation exposure.

- Glass barriers absorb or reduce the intensity of radiation while allowing visual contact between medical personnel and patients.

Equipment is only effective when it is worn properly and consistently and provides adequate protection necessary from the radiation source. Employers should inspect equipment regularly for signs of damage.

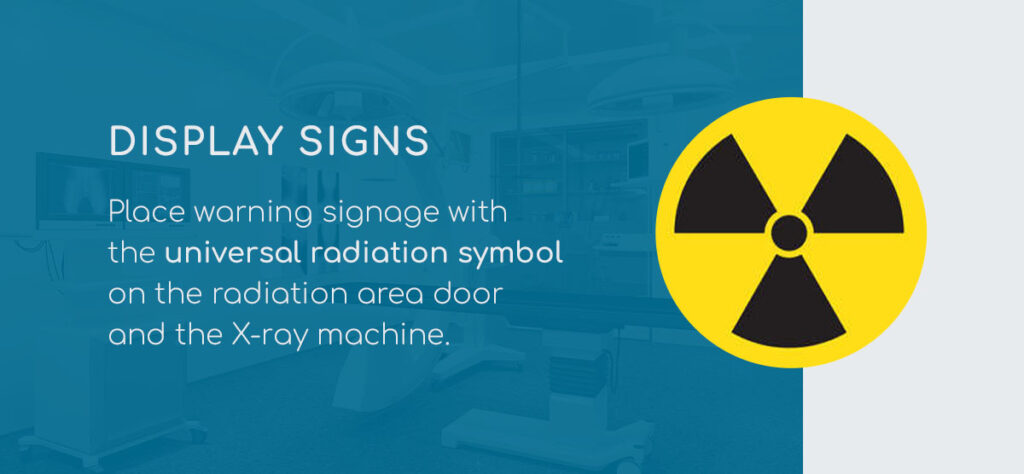

Display Signs

Each radiation area door and machine must be conspicuously posted with a sign or signs with the radiation caution symbol and the appropriate language that identifies the levels at which radiation exists.

- Caution Radiation Area: this sign is used to indicate areas where radiation exists at such levels that a major portion of the body could receive a dose in excess of 5 mrem per hour, or in any 5 consecutive days a dose in excess of 100 mrem.

- Caution High Radiation Area: this sign is used to indicate areas where radiation exists at such levels that a major portion of the body could receive a dose in excess of 100 mrem per hour.

These cautionary signs let everyone, including patients, know there is a potential for radiation exposure in that area.

Employee Training

OSHA requires medical and dental practices to provide yearly training to staff members to make them aware of radiation risks and to train workers on safe work practices. Employers should provide workers with information and training to ensure those who are potentially exposed to ionizing radiation hazards understand how to safely use all radiation-producing equipment or radiation sources in the workplace.

Developing and Implementing a Radiation Safety Plan

Maintaining OSHA compliance in radiology is essential – not only for protecting employees who work with radiation but also for ensuring patient safety and meeting regulatory requirements. For medical and dental practices, radiology safety should be a key component of a comprehensive OSHA compliance program that addresses all workplace hazards.

By incorporating radiology-specific protocols into your overall policies, procedures, and training, you can create a safer environment, reduce risks, and foster a culture of compliance throughout your practice. If you’re unsure whether your current OSHA program fully addresses radiology safety – or if you need help developing or updating your policies – we can help. Contact us to learn how we support medical and dental practices in building effective, customized OSHA compliance programs that include radiology safety.